To verify the safety and reliability of Mega Radar products, we perform extensive material, electrical and mechanical testing. From the development process, during and after manufacturing, we carry out procedures subject to the integrated management systems ISO 9001, ISO 14001, ISO45001 and ISO10002.

- Material testing: Measurement of material suitability, long-term behavior under specific conditions

- Mechanical tests: Product resistance to severe external influences (bending, fracture, deformation of surfaces)

- Electrical tests: Current voltage characteristics, insulation and current carrying capacity properties

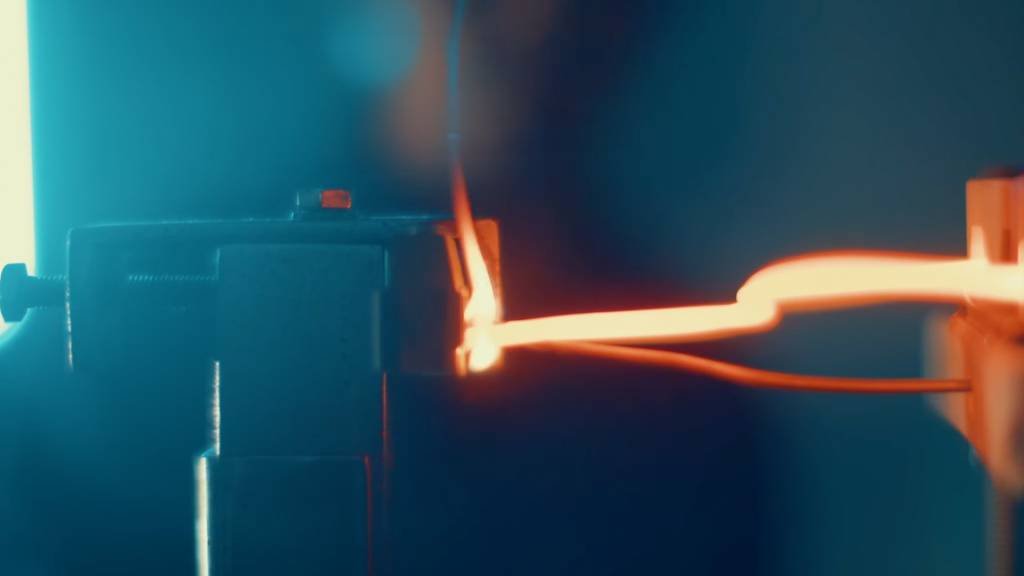

Incandescent Wire Test

(TS EN IEC 60947-7-4, IEC 60695-2-11, IEC 60695-2-10)

Purpose of the test: To measure durability under extreme temperature conditions. The tip of the glow wire at 850°C is applied for 5 seconds to the specified surface of the specimen, taking into account the normal conditions of use under which a heated object may come into contact. It is important that the material does not burn, catch fire or drip.

Rotation/Torsion Test

(TS EN IEC 60947-7-4, TS EN 60999-1)

Purpose of the test: To measure the grip strength of the terminal block on the cable.

In the Rotation/Torsion Test, the conductors are connected to the compression unit. Weights specified in the standard are connected to the other end of the conductor and positioned in a circle with a diameter of 75mm and rotated for 15 minutes.

During the test, the conductor shall not slip out of the clamping unit, shall not break in the vicinity of the clamping unit, and shall not be damaged in such a way that the conductor cannot be reused.

Tensile Test

(TS EN IEC 60947-7-4, TS EN 60999-1)

Purpose of the test: To measure the grip strength of the terminal block on the cable. In the tensile test, the conductors are connected to the compression unit. Weights specified in the standard are connected to the other end of the conductor and tested with weights for 1 minute. During the test, the conductor (cable) must not slip out of the clamping unit (clamp of the terminal block).

Insulator Test

(TS EN IEC 60947-7-4)

Purpose of the test: Measurement of current carrying capacity characteristics. The terminals to which the conductors are connected shall be subjected to a specified level of high voltage for 1 minute. The test voltage shall be applied between each pole, which in practice can take different potentials. No destructive discharge or voltage drop of the test voltage is allowed during and after the test.

Temperature Increase Test

(TS EN 60998-1)

Purpose of the test: To evaluate the current carrying capacity of electromechanical components at elevated ambient temperature. The terminal block is held in a housing and connected to a power supply. Temperature rise measurements are made on the terminal block with the current. The measured temperature value must not exceed the degree upper limit (DUL).

Ball Pressure Test

(TS EN IEC 60947-7-4)

Purpose of the test: To measure product resistance under external mechanical influences. The test is performed in a heating cabinet at 125°C. The ball is placed on the terminal block and kept in the heating cabinet and at the end of the test, the dent caused by the ball on the material is measured, this value should not be greater than 2 mm.

Rotary Drum Test

(TS EN 60998-1)

Purpose of the test: To measure product resistance under external mechanical influences. The specimens, whose screws are tightened with the appropriate torque, are thrown into the rotating drum and the test is carried out for 50 drops. After the test, the specimens shall not show any fractures, cracks or deformations that would prevent them from being protected against electric shock.